OSHA Hand Washing Requirements at a Worksite (2025)

OSHA Hand Washing Requirements at a Worksite (2025)

Hand washing isn't exactly the most thrilling workplace topic, but it might be one of the most critical.

OSHA doesn’t just suggest it – they require it, with real consequences for getting it wrong.

We’ll break down exactly what the rules say, how to meet them, and where portable handwashing stations come in when permanent setups fall short.

Key Summary

- OSHA requires specific sink locations, water temperatures, and soap types for compliant hand washing stations.

- Industry-specific requirements vary significantly between healthcare, food service, and manufacturing environments.

- Proper training documentation and regular compliance audits help avoid costly OSHA violations.

- Alternative solutions exist for workplaces where traditional hand washing facilities aren't feasible.

OSHA Hand Washing Requirements

OSHA's regulations on hand washing are primarily outlined in standard 29 CFR 1910.141, which covers sanitation requirements for general industry workplaces.

The specific provisions for hand washing facilities are found in sections 1910.141(d)(2)(iii) and 1910.141(d)(2)(iv).

These regulations stipulate that employers must provide:

- Hand washing facilities in all places of employment

- Adequate running water (hot and cold, or tepid)

- Hand soap or similar cleansing agents

- Hand-drying facilities (such as paper towels or air dryers)

- Facilities that are maintained in sanitary condition

Non-compliance can result in citations and fines ranging from $15,625 per violation for serious violations to $156,259 for willful or repeated violations (as of 2023).

Beyond financial penalties, inadequate hand washing facilities contribute to increased employee illness, absenteeism, and reduced productivity.

Implementing Effective Hand Washing Techniques

Proper hand washing technique is as important as having the right facilities. OSHA recommends following CDC guidelines, which include:

- Wetting hands with clean running water

- Applying soap and lathering all surfaces

- Scrubbing hands for at least 20 seconds

- Rinsing thoroughly under clean running water

- Drying with a clean towel or air dryer

Training and Employee Engagement

Effective hand hygiene programs require more than just installing sinks and posting signs.

Employee training should:

- Demonstrate proper techniques

- Explain the rationale behind requirements

- Address common misconceptions

- Use visual aids and hands-on practice

- Include periodic refresher training

Designing and Maintaining Hand Washing Facilities

The design of hand washing stations significantly impacts compliance rates.

OSHA-compliant facilities should consider:

Location and Accessibility:

- Stations must be located in or adjacent to toilet facilities

- Maximum distance from work areas should allow reasonable access

- Facilities must accommodate workers with disabilities

- Clear pathways must be maintained to hand washing stations

Equipment Requirements:

- Sinks must be of sufficient size and depth

- Faucets should ideally be hands-free (sensor-activated or foot-pedal operated)

- Soap dispensers should be regularly filled and maintained

- Paper towel dispensers or air dryers must be functional

- Trash receptacles should be provided near paper towel dispensers

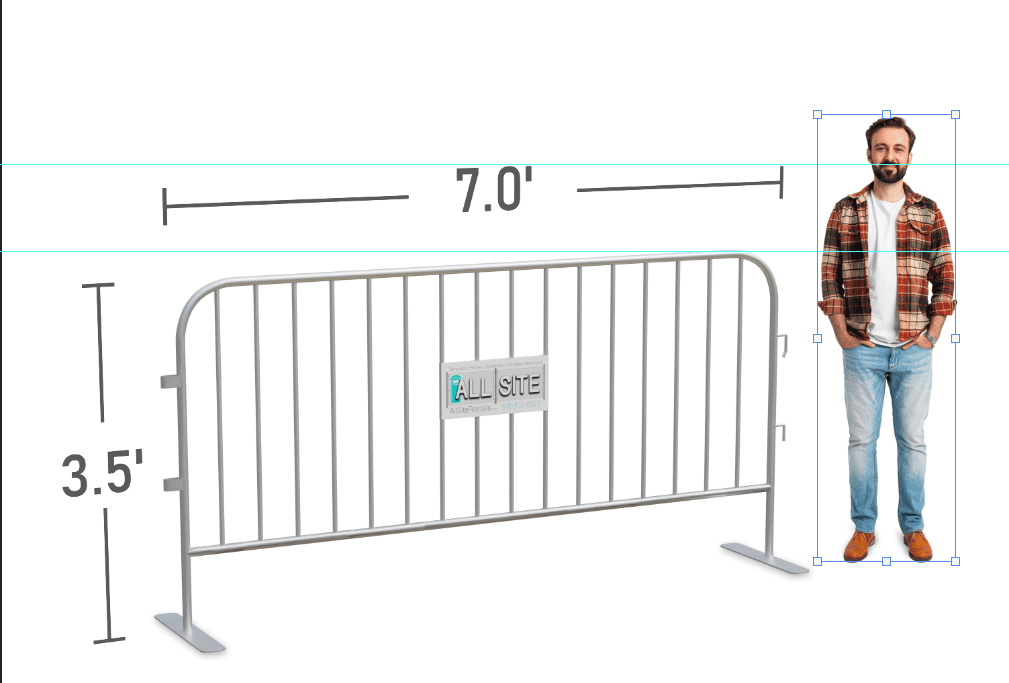

When Permanent Facilities Aren’t an Option

Not every jobsite or event location can support built-in plumbing and that’s where portable handwashing stations come in.

OSHA allows for alternative solutions in remote, temporary, or outdoor settings as long as they meet the same basic requirements: access to clean running water, soap, drying options, and sanitary upkeep.

Whether you're managing a construction site, food stall, or seasonal pop-up, mobile units can keep you compliant without the cost or logistics of permanent infrastructure.

Just make sure they’re strategically placed, easy to access, and regularly maintained.

Integrating Hand Washing into Broader Safety Protocols

Hand washing requirements don't exist in isolation. They're part of a comprehensive approach to workplace safety and health.

Effective integration includes:

Connection with Infection Control:

- Hand hygiene as the first line of defense against infectious disease

- Coordination with respiratory protection programs

Relationship with PPE Usage:

- Hand washing before donning gloves

- Proper hand hygiene after removing PPE

Frequently Asked Questions

How often should OSHA compliance audits for hand washing stations be conducted?

While OSHA doesn't specify a mandatory frequency, quarterly audits are recommended as best practice, with more frequent checks in high-risk environments like healthcare or food service.

Can hand sanitizer stations replace traditional hand washing sinks in certain workplaces?

Hand sanitizers can supplement but not replace hand washing stations in most workplaces. However, OSHA allows exceptions in certain field operations where water is unavailable, provided proper documentation and alternative methods are implemented.

What documentation should employers maintain regarding hand washing compliance?

Employers should maintain records of station installation dates, maintenance logs, employee training completion, inspection results, and any corrective actions taken to address deficiencies.

What are the penalties for non-compliance with OSHA hand washing requirements?

Penalties vary based on violation severity, ranging from $14,502 per serious violation to $145,027 for willful or repeated violations (as of 2023). Additional costs may include legal fees, increased insurance premiums, and reputational damage.

Conclusion

OSHA’s hand washing requirements might seem straightforward, but there’s more to them than just placing a sink in the corner.

From the type of soap to how far the nearest hand washing station is from a work area, compliance takes intention.

Whether you're operating in food service, healthcare, or general industry, keeping facilities accessible, well-maintained, and paired with effective training can go a long way in avoiding violations and promoting workplace health.

Need a reliable, fully compliant handwashing station for your site? Get a free quote today – no pressure, just practical solutions.